The construction industry faces a number of health and safety challenges on a daily basis. One of them is how to transport materials from ground level to the floor on which they will be used. We have done something about these challenges..

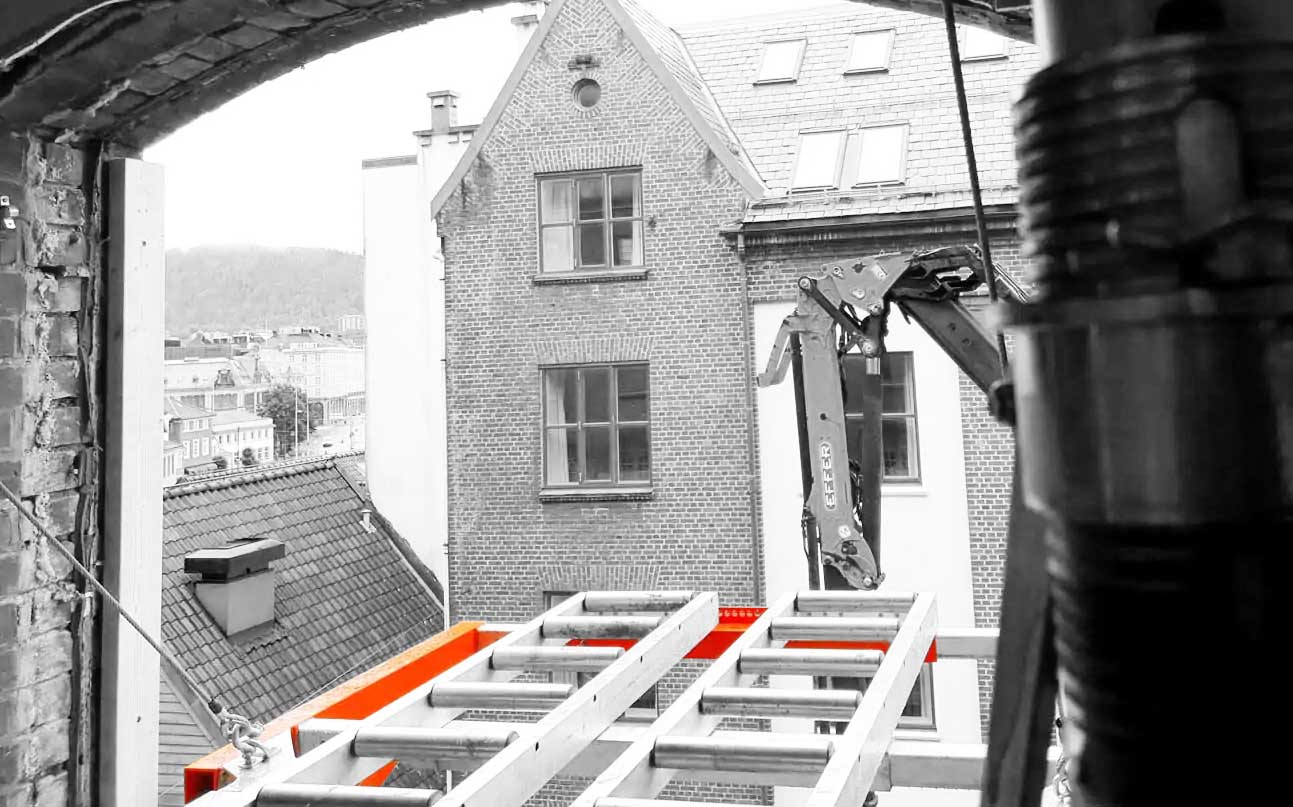

The Liftroller system comprises a range of products developed to solve logistical challenges on building sites. The system is used on building projects for faster, easier and safer transportation of materials into buildings. The Liftroller system is equipped with rollers for increased efficiency and safety as well as minimal strain on the workers.

Faster, easier and safer construction site logistics.

The Liftroller system comprises portable components which are assembled to form a conveyor belt with rollers from the outside to the inside of the building. We have also developed a range of accessories to ease onward transportation of the materials inside the building.

To maximise the benefits of the Liftroller system, it can be used to transport materials and equipment into the building and to remove waste from the building.

Every building project is unique, and we can help you identify which products are best suited to the limitations and opportunities that exist on your building site. Take a look at some of our projects here.

Faster construction site logistics

- Uninterrupted operation

- Faster unloading

- Less waiting

- Fewer operatives needed to do the job

- Save time and money by not having to apply to use the pavement

Uninterrupted operation

Faster unloading

Less waiting

Fewer operatives needed to do the job

Save time and money by not having to apply to use the pavement

Easier construction site logistics

- No need for temporary access

- Cuts rigging costs

- Lightweight, easy to assemble

- Easy to use

- Flexible – can be used in many different types of buildings

- Materials can be delivered the day they will be used

No need for temporary accessway

With the Liftroller you simply use existing openings in the façade. On renovation projects you do not have to cut large openings or expand window apertures to get materials on site. Rebuilding walls is costly, and building control will often want to have a say.

On newbuilds you can roll materials and equipment into the building at an early stage by using the Liftroller Floor. The lifting platform does not have to be fitted to a wall as it is secured against the floor and ceiling. You can also complete the façade and use one of the planned windows instead of leaving temporary accessways open till the last minute.

Cuts rigging costs

Lightweight, easy to assemble

Easy to use

Flexible – can be used in many different types of buildings

Materials can be delivered the day they will be used

Safer construction site logistics

- Reduces risk of injury to workers and increases safety

- Eliminates carrying and heavy lifting, makes work more enjoyable

- Save time and money by not having to apply to use the pavement

Reduces risk of injury to workers and increases safety

Eliminates carrying and heavy lifting, makes work more enjoyable

Prevents hazardous situations caused by improvised solutions